Solving Tomorrow's Complex Problems today!

410-857-0770

Email: [email protected]

LAI International

1110 Business Pkwy S.

Westminster, MD 21157

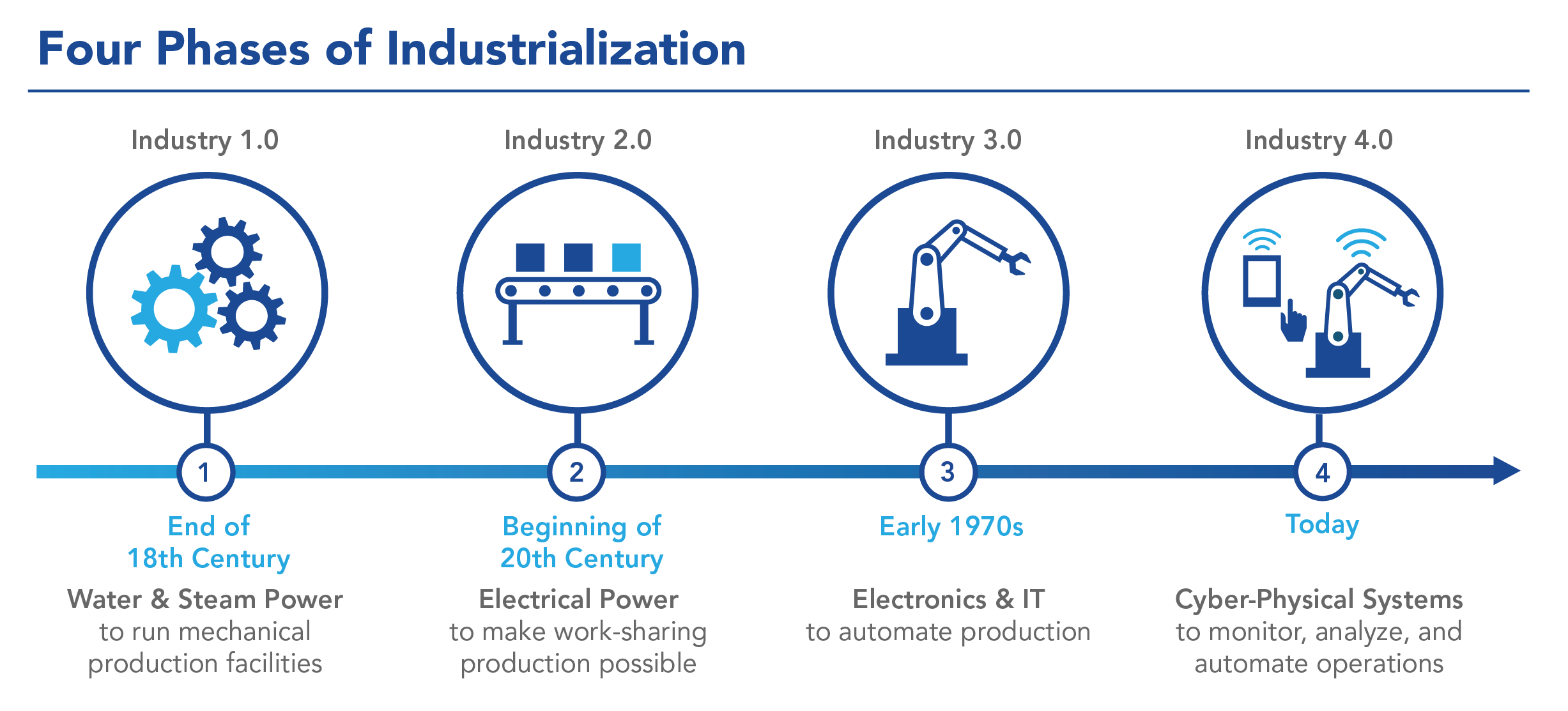

As we shared back in August 2017 and later in April of this year about our view of Industry 4.0, we would like to share what we have learned along the way. As we noted in earlier articles we are looking to gain these 6 areas of Increased competitiveness of businesses, Increased productivity, Increased revenue, Increased employment opportunities and enhanced human and IT resources management, Optimization of manufacturing processes and Delivery of better customer service.

Setting up our Structure within Manufacturing 4.0

Our CEO, Patrick PJ Gruetzmacher, presented our progress to the Manufacturing Leadership Council and the 123 companies represented at their annual Summit and Awards event held in Huntington Beach, California. LAI was in attendance again to receive 3 awards, 1 of which is tied to our Manufacturing 4.0 journey.

LAI International was honored to be the recipient of three Frost & Sullivan’s Manufacturing Leadership awards at last month’s Manufacturing Leadership Summit held in Huntington Beach, CA., on Wednesday, June 13.

The ML Summit is a unique, interactive gathering of manufacturing leaders from around the world.

The theme for the 2018 Summit was fitting, “Accelerating the Transformation to Manufacturing 4.0”. The prestigious ML Awards program honors organizations and individuals that are shaping the future of global manufacturing.

LAI International received awards in the following categories:

- Collaborative Innovation Leadership

- Engineering and Production Technology Leadership

- Enterprise Integration Technology Leadership

“The companies, projects and individual leaders being honored with 2018 ML Awards are redefining excellence by embracing the technology-driven transformation that we call Manufacturing 4.0,” said Global Vice President, Editorial Director and Co-Founder of the Manufacturing Leadership Council David R. Brousell. “Their inspiring achievements are allowing their companies to anticipate and thrive through the dramatic changes now rippling through the global manufacturing marketplace.”

LAI International Inc. knows that to be an aerospace and defense industry supplier that it needs to be in metal additive technology.

LAI International’s established pattern of growth is seen both in the addition of facilities placed throughout the U.S. and the adoption of fabricating and machining technologies.

Laser Applications Inc. (LAI), founded by Robert Ulrich in 1979, initially offered laser welding and laser heat-treating processes. Waterjet, laser drilling, and cutting capabilities soon were added, along with facilities in Westminster, Md., Minneapolis, Minn., and its headquarters in Tempe, Ariz.

* Reprinted with permission from The Additive Report, Fall 2018, FMA Communications Inc.

Last month, I had the privilege of presenting a LIVEWORX, the world’s leading technology conference and industrial marketplace that focused on the most innovative and disruptive technologies – Internet of Things (IoT), Augmented Reality (AR), machine learning, blockchain, Artificial Intelligence (AI), robotics and more.

My presentation titled “Printing Metal: Powder Bed Fusion for Aerospace Applications”, focused on machines and determining the right parts and application to print good quality product.

To say metal additive manufacturing has grown rapidly in the last five years is an understatement. Within the powder bed fusion space, there are over 90 machines available, and each one has unique attributes that impact the success of your parts.

With more users trying the technology every day, how does one pick a platform? Answering this question requires a complete understanding of the requirements for your application and diving deeper into seven key attributes of metal powder bed fusion equipment:

- Defining the Metallurgical process

- Robust Equipment Control Plan

- Robust Training Plan

- Qualifying Metallurgical Process

- Building Material Capability Database

- Having a Qualified Part Process

- Creating and maintaining Process Control Documents

A common question in powder bed fusion is "will my part fit" but there is more to the build envelope equation than dimensions.

The impact of the seven key attributes in a variety of case studies will allow users to make educated decisions when making the jump into metal additive manufacturing. If you are interested in Additive Manufacturing and what is needed to implement this technology into production for Aerospace & Defense applications, contact Adam Rivard, Additive Manufacturing Director at LAI International: [email protected] 207-756-5544.