Solving Tomorrow's Complex Problems today!

410-857-0770

Email: [email protected]

LAI International

1110 Business Pkwy S.

Westminster, MD 21157

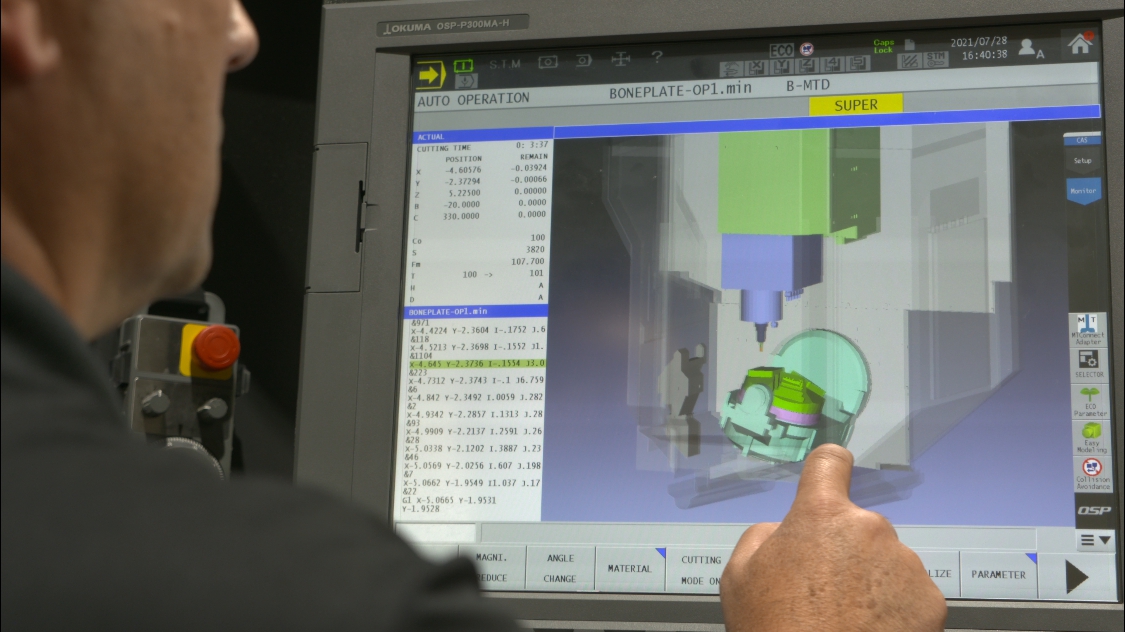

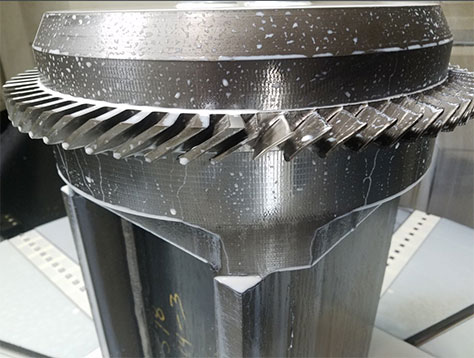

5-axis machining is unique in its ability to effectively process part sizes and shapes with essentially infinite possibilities. Like 3-axis machines, the cutting tool of a 5-axis machining center moves across the X, Y, and Z linear axes, but also rotates on the A and B axes – allowing the cutting tool to approach components from any direction.

An experienced machinist can achieve incredibly complicated geometries with high precision when using all 5 axes in conjunction. The skilled machinists, operators, and programmers at LAI International are capable of machining complex shapes, and complicated angles – all in one setup.

The ability to machine a component to completion in a single setup not only adds to the precision achieved during machining but also reduces tooling costs, overhead costs, and labor time, resulting in the lowest possible cost per part.

5 axis machining centers eliminate several inadequacies of conventional CNC machining techniques, including multiple setups, part transfers, and inspections; part handling, and errors associated with human involvement/interference.

Our Equipment

Okuma MU-4000V

Our MU-4000V 5-Axis CNC Vertical Machining Center combines high efficiency and accuracy to deliver high-quality workpieces with many machined portions. Simultaneous 5-axis surfacing and turning enables one-chuck multi-sided machining, along with outstanding surface quality and dimensional accuracy. With one of the largest work envelopes in its class, this machine provides the flexibility to handle a wide range of workpieces while maintaining the most compact footprint possible.

Specs

| Max Machining Volume | in | X: 29.13 Y: 18.11 Z: 18.11 |

| Table Size | in | Ø15.75 |

| Spindle Speed | min⁻¹ | 15,000, [20,000, 25,000] |

| Spindle Motor Power | hp | 30/25 |

| Rapid Traverse X-Y-Z | ipm | 1,969 |

| Rapid Traverse | deg/min | B: 18,000 (50 min ⁻¹) C: 43,200 (120 min⁻¹) |

| Magazine Capacity | 32-tool [48-tool, 64-tool: chain, over 64-tool: matrix] |