LAI International is renowned for our cutting-edge precision component manufacturing solutions that help OEMs meet production goals by delivering high quality complex components on time, every time, at the right value.

Solving Tomorrow's Complex Problems today!

410-857-0770

Email: sales@laico.com

LAI International

1110 Business Pkwy S.

Westminster, MD 21157

Our manufacturing capabilities

5-axis machining is unique in its ability to effectively process part sizes and shapes with essentially infinite possibilities. Our skilled machinists, operators, and programmers at LAI International are capable of machining complex shapes, and complicated angles – all in one setup.

3-AXIS CNC MACHINING

3-axis milling is well-suited for milling simple parts, large parts, or high volume parts. Our 3-axis milling works well for high volume material removal, providing increased accuracy and efficient machining of a wide range of parts.

SWISS-STYLE CNC MACHINING

Our state of the art Swiss-style CNC equipment and highly skilled technicians can manufacture very small parts within near-perfect tolerances.

ELECTRICAL DISCHARGE MACHINING

We offer HSD, precision hole, wire, and plunge EDM processes for all complex precision metal parts.

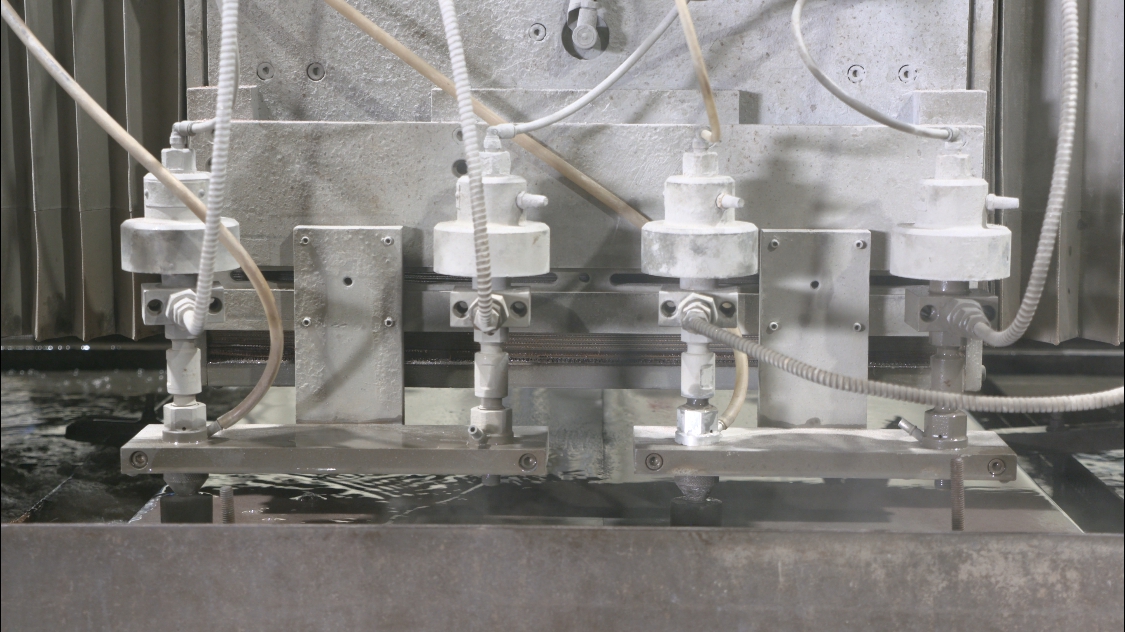

5-AXIS WATERJET MACHINING

Used for more specialized parts, 5 Axis Water Jet cutting has the ability to create irregular 3 dimensional shapes where conventional drilling or machining may not be possible. Material up to 15 inches thick can be cut.

3-AXIS WATERJET MACHINING

Our 3 Axis Water Jet cutting facility is one of the largest in the USA with capacity to produce high volume parts. We have over 40 years of experience with this process. The process is used for cutting parts from soft or hard sheet metal up to 15-inch thickness. As the Water Jet cutting process does not impart heat into the work piece, it is often used where conventional cutting cannot be used.

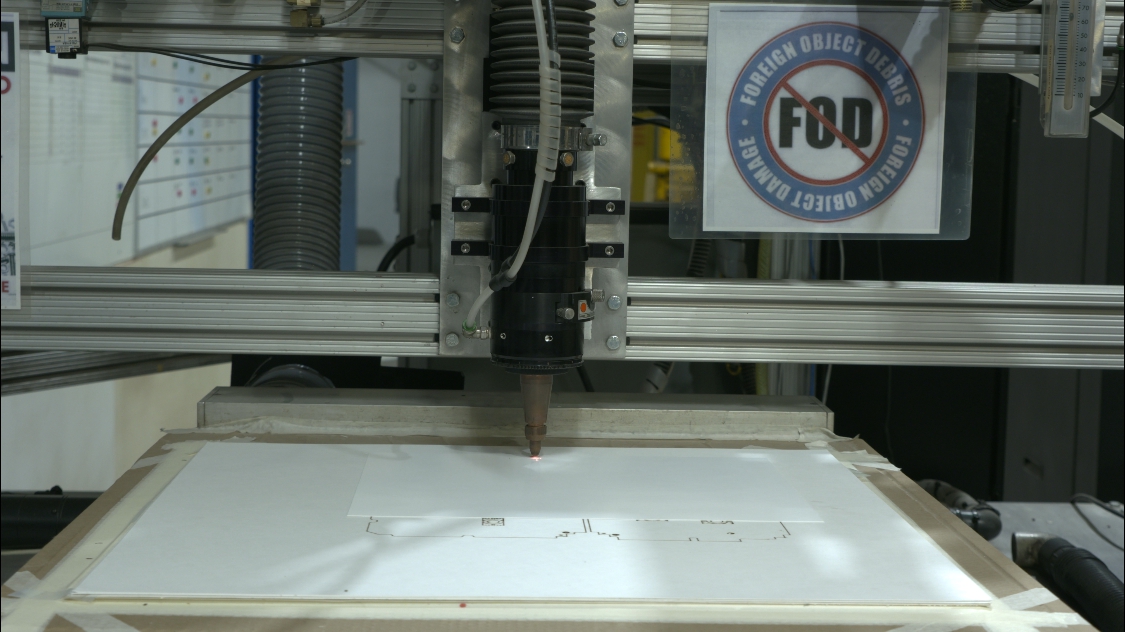

LASER CUTTING

We offer laser cutting, drilling, welding and heat-treating to provide our customers unique, wide-ranging solutions for their difficult engineered components.

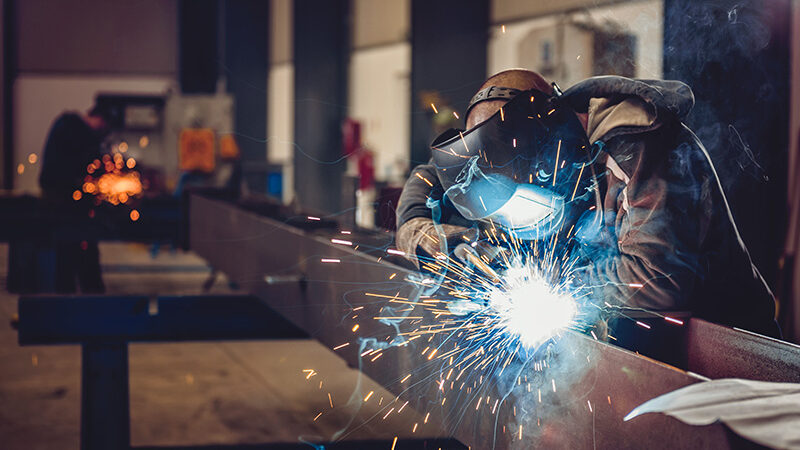

WELDING

We provide excellent in-house welding capabilities. Our company employs an experienced welder with multiple certifications. Our welded products are certified to MIL-STD-1595A, MIL-STD-2219, AWS D1.1, AWS D1.2, AWS D1.3 and AWS D1.6.

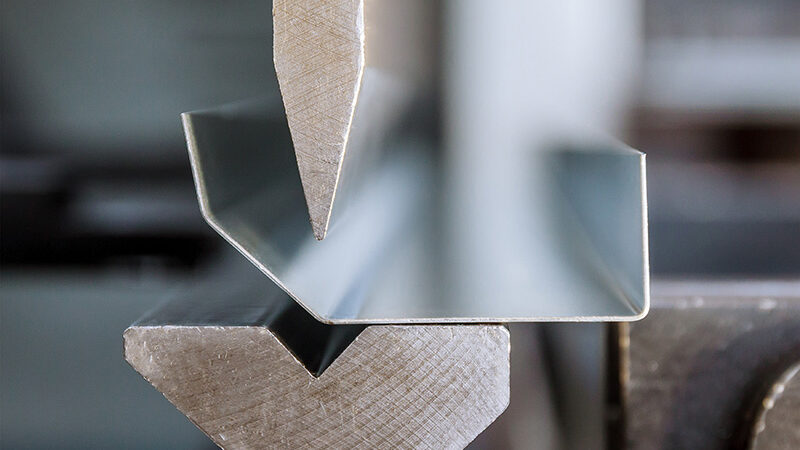

SHEET METAL

We provide Precision Electronic Sheet Metal Fabrication of parts and components to our customers’ specifications. Our Fabrication Department includes computer controlled punching, forming, metal grinding, and mechanical assembly.

FINISHING

Our Finishing Department offers ROHS compliant in-house conversion coating to MIL-DTL-5541F Type 1 and Type 2. Our company can also offer passivation to ASTM-A967 and SAE-AMS-QQ-P-35. We have full military compliant and commercial painting capabilities, including the application of CARC paints to MIL-DTL-53072C. We also offer special marking and silk-screening to MIL-STD-130.